The capabilities of Glass + Metal Craft are deep and wide-ranging. Clients come to us for the design and fabrication of custom architectural systems, to tens-of-thousands of square feet of insulated glass, to shower doors and mirrors for corporate venues and home settings, and more.

We are different, in a very good way, from other leading glass fabricators.

Architectural Systems

Glass + Metal Craft designs and fabricates premier architectural systems for customers nationwide. Our capabilities range from glass and metal vestibules, to canopies, structural walls, stairways, guardrails, and windscreens, as well as decorative glass.

Our Fulcrum Architectural Design Assist Division provides on-demand technical consultation. Above all, we help you get your project on track with the right glass and/or metal elements. And then we stay involved to ensure a successful completion.

Only Glass + Metal Craft offers Assured Fitment™: that is, retain G+MC to take the on-site measurements for an architectural system, and we guarantee it will fit within the intended space envelope or we will make any required changes at our cost. Because customer satisfaction matters!

Assured Fitment is an extension of our involvement as the design engineer of the system. As a result, we inherently understand what needs to be measured. With this knowledge, a G+MC technician comes to the installation site, and uses laser-based technology to assess dimensions accurately in 3D to .9 mm at 10 meters. Consequently, we insert the measurement data directly in the CAD for the system. Assured Fitment enables us to get it right the first time – and deliver an architectural system on time and at intended cost.

We deliver our architectural systems with stamped engineering drawings, and kit all our products to flow installation.

Further, G+MC engineers can provide curved and ballistics glass or metal elements.

Hardware

G+MC’s Cuda Metal Division offers unique in-house capabilities for custom or modified architectural hardware using primarily heavy stainless and painted mild-steel.

We inventory or otherwise have access to a broad array of off-the-shelf hardware to meet glass entrance door and shower hardware.

Fabricated Glass

Glass + Mirror Craft is the glass fabrication division of Glass + Metal Craft. Through this division, we offer a full spectrum of fabricated and laminated glass solutions for both residential and commercial users. These capabilities include architectural systems, shower doors, and decorative applications, both in low-volume and for large-scale projects.

We inventory the most common flavors and thicknesses of clear, low-iron, acid etched, tinted, and satin glass. Further, we offer multiple spandrel options. Our professional commercial team can assist customers in finding the latest color solutions.

What makes us unique in the fabricated and laminated glass arena:

Our team is dedicated to getting things done on-time and right the first time.

We offer super jumbo size capability – up to 130” x 236” – using industry leading, automated equipment from Glaston, CMS, and Lisec. In total, we deliver the flattest, highest quality glass results.

We fabricate glass to stringent customer request: placing holes, notches, and cutouts where they are required with world-class precision and polishing or beveling edges to a beautiful luster.

Our skilled craftspeople are able to produce multi-ply laminated panels with ionoplast (SentryGlass) or EVA interlayers.

Our creative team can silk screen, sandblast, etch, back paint, and provide laminated panels with colored or printed interlayers.

Insulated Glass

G+MC is a leading fabricator of insulated glass (IGs), serving the nation for for more than 50 years. Our wide capabilities in IGs differentiate ourselves from our competition by:

We make the highest quality IGs, with clean edges and faces, neatly packaged.

Moreover, our company offers a complete range of IGs – from standard 1/4” lites to heavy glass lites, up to 1/2” monolithic and 9/16” laminated, and offset edges. We seal our units using either silicon or butyl, and feature precision-drilled point-support holes when delivered as part of our architectural systems. G+MC equips our standard IGs with a wide variety of muntin bars.

We uniquely provide raised edges on the exterior lite for clean, butt-joined applications.

Further, we stock or have access to Guardian products, the world’s best Low-E and bird-friendly coatings. We frequently incorporate 8mm, 10mm and 12mm glass in our IGs for the absolute flattest IGs on the market.

In addition, we produce and guarantee (through a 10-year warranty) Point Supported IGs with Low-E glass that feature holes, pucks or cassette spacers.

We are certified to produce IGs with a broad array of warm-edge spacer types and thicknesses.

G+MC delivers glass directly to jobsites on flatbeds with Moffett hi-los.

We monitor market demand and quickly adjusting our offerings and inventory positions.

Finally, we have processes in place to expertly feed our glazier partners’ unitized systems.

Glass Configurations

G+MC provides flat and curved insulated glass, laminated glass, insulated laminated glass, tempered glass, and monolithic clear, low-iron, satin-etched and textured glass.

We provide inboard or outboard Insulated laminated glass options that combine temperature control with the added safety of lamination. It also allows near limitless possibilities in terms of tinting, silk-screened patterns, coatings and more.

G+MC is certified to produce and market ballistics glass as a complementary addition to our glass offerings.

We fabricate glass to exacting customers’ requests— placing holes, notches, and cutouts where they are required, including through the use of a Forvet large scale CNC for jumbo glass products.

Diamon-Fusion Protective Coatings

Glass + Metal Craft offers the outstanding protection of Diamon-Fusion, an optically clear, protective coating that permanently seals the peaks and valleys of glass. The addition of Diamon-Fusion to G+MC glass greatly improves stain resistance, makes the glass easier to clean, protects the glass from pollutants and scratches.

Diamon-Fusion is UV resistant and eco-friendly, and can also contribute to LEED points as it is approved by the United States Green Building Council (USGBC) as a protective coating.

In addition to DFI, G+MC has access to the entire catalog of coatings and substrates from the flagship plant of Guardian Glass in Carleton, MI.

G+MC can silk screen, sandblast, etch, back paint, and provide laminated panels with colored or printed interlayers—from 6” x 6” squares to jumbo size offerings.

Glass Heat Treatment

G+MC’s tempering ovens allow thermal treatment to strengthen the glass and reduce the damage that could result from breakage (small granular chunks rather than jagged shards).

Our capabilities range from hand-size to jumbo glass sheets, with output monitored by an in-line Fennevision scanner, which automatically checks for scratches, chips, pocs, roll distortion, and other imperfections.

We adhere to the requirements, tolerances, and testing procedures for heat-treated glass as defined in ASTM C1048 Standard Specification for Heat-Strengthened and Fully Tempered Flat Glass.

Quality

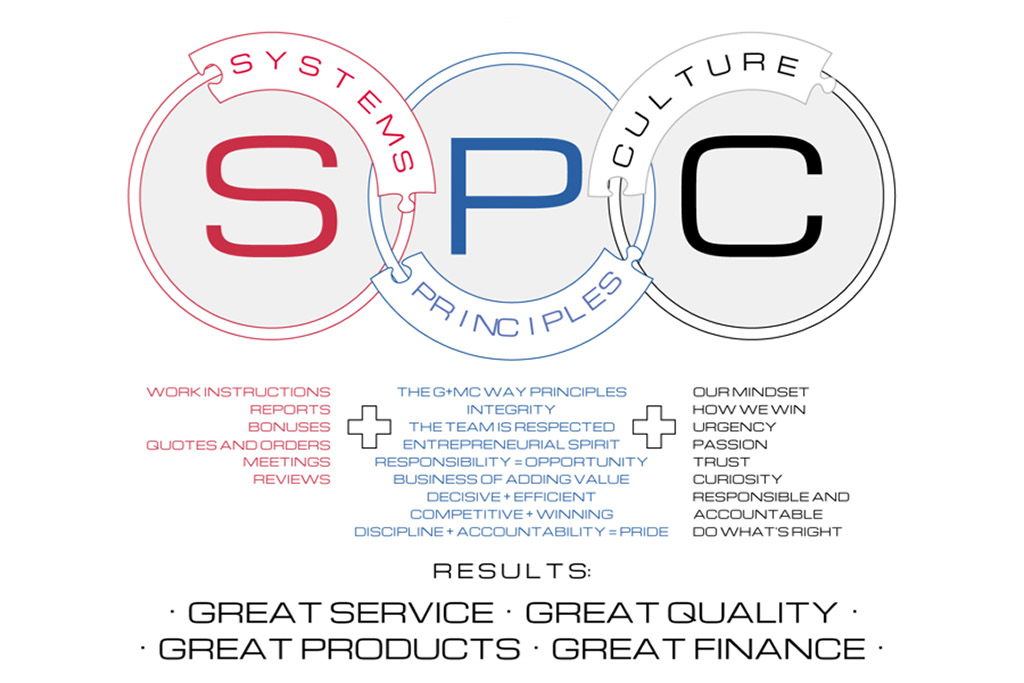

The consistent practice of our Business Perspectives results in a culture that provides great quality, great service, great products, and great finances.

Our Quality Philosophy is that a company, like people, should grow each year in vision, in performance, and in accomplishments. To achieve this vision, we are committed:

To total customer satisfaction attained through training and solving problems at the root cause.

To continuous improvement in products and services, and understanding that workplace safety and cleanliness are the cornerstones to do so.

To open, ongoing communications among team members.

And to strong, profitable partnerships with our customers and suppliers.

Logistics and Shipping

Our capabilities, here, are also very strong. G+MC maintains a fleet of Class 7 flatbed trucks, equipped with Moffett hi-los, to deliver glass directly to jobsites. We work with third-party shipping companies to transport our glass outside the Midwest.

For Insulated Glass, G+MC continues to focus on the 250-mile radius around Wixom that can easily be serviced by our logistics team. We do, however, also provide project glass throughout the country in areas where our value is recognized.